GENERAL

It is used to dry products which are extremely difficult to produce in powder form using conventional drying technologies.

The PFSD combines fluidization and spray drying technologies,enabling the size and structure of particles to be easily controlled. Therefore, the PFSD is often used as a spray dryer granulator. Drying is completed while very low powder important feature which makes this concept ideal for producing heat sensitive products in dried form.

Product particle sizes are as the following:

1. Powder products (average particle size 50 ~ 100 micron)

2. Grain products (average particle size of 150 ~ 400 micron)

3. Fine products (average particle size 70 ~ 120 micron)

Product quality is controlled by main process parameters, such as product moisturecontent, particle structure, particle size distribution, solubility, mixing, wetting, to maintain the original taste and flavor.

High quality and reliable parts for the equipment efficiency, longer life-line cleaning systems (CIP) to the greatest extent possible to extend the effective production time.

FEATURES

- Produces free flowing powders in agglomerated or granulated form.

- Produces powders having a very low content of small particles(dustless)

- Dries many thermoplastic and hygroscopic products that area problematic in other designs.

- Ideal for heat sensitive products as particle temperatures are kept low throughout the drying process.

- Drying is completed at low outlet drying temperatures,giving high energy utilization efficiencies.

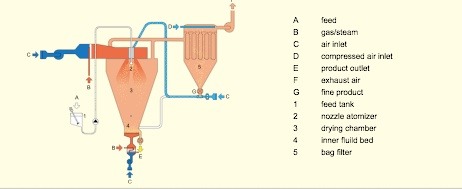

MAIN COMPONENTS

The main components of the spray dryer consists of

- Atomizer - Nozzle or rotary atomizers are used to spray the feed liquidinto droplets.

- Air disperser - A roof-mounted design controls the air flow pattern in the drying chamber.

- Hot air system - Provides hot air for drying. Incorporates oil, gas, steam, and electrical heating units.

- Drying chamber - Cylindrical chamber with a fluid bed mounted in the conical base.

- Exhaust air system - Separates airborne particles from the drying air leaving the drying chamber.

- Powder handling - In pneumatic or vibratory systems, or vibratory systems, or externally mounted fluid beds.

APPLICATIONS

Chemicals - Detergents, Dyestuffs, Ingornic and organic salts, Pesticides, Tannins

Pharmaceuticals - Antibiotics, Blood plasma, Enzymes, Vitamins, Polymers, e-PVC, Styrene copolymers, UF, PF resin

Food products - Coffee, Diary products, Eggs, Fermentation products, Flavours malt extracts, Maltodextrine, Soup mixes, Vegetables proteins (hydrolysed), and Yeast.

PROCESS FLOW DIAGRAM