GENERAL

Hot Circulation Oven

Hot air circle oven is suitable for heating and solidification, drying and dehydration of raw materials. The raw materials such as dyestuff, pigment, powder, granule, dehydration vegetables and so on.

WORKING PRINCIPLE

Hot air circle is equipped with low noise axial flow fan and automatic temperature control system. The air circulation system is fully sealed. It makes the hot efficiency increase from 3-7% of traditional oven to 35-45%. The maximum hot efficiency can be 70%.

FEATURES

- Most of hot air is circulated inside the oven. The efficiency is high and the energy source can be saved.

- It is equipped with adjustable air distribution plate to ensure uniform airflow inside the oven. Raw material can be dried evenly.

- The machine has low noise and stable operation. The temperature can be controlled automatically.

- The installation and maintenance are very convenience.

- The application fields are wide and suitable for many types of raw materials.

- Material of construction is SUS304 or SUS316 based on Client requirement.

- Heating method is electrical heater or steam heater based on Client requirement.

- GMP oven can also be supplied based on Client requirement.

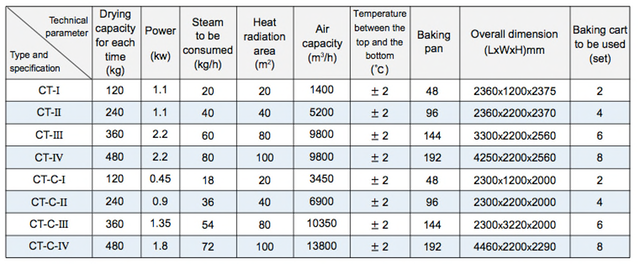

TECHNICAL SPECIFICATION