standard Spray dryer

GENERAL

Standard rotary atomizer spray dryer is suitable for spray drying solution, emulsion, suspension and paste into powder form with high efficiency and less processes.

Dried materials has good dissolvability and high purity. The machines have a good working condition and can be operated automatically dependson Client requirement.

WORKING PRINCIPLE

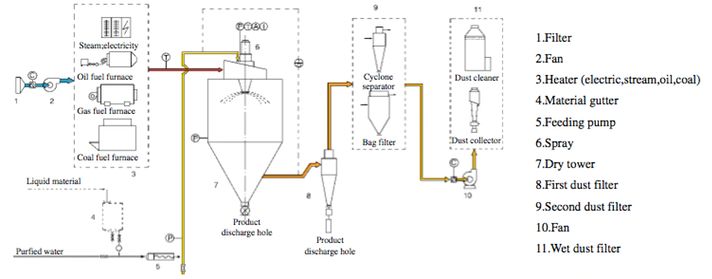

Initially the fresh air is filtered and heated before entering drying chamber thru the air distributor system which is located on top of the drying chamber. The hot air enters the drying chamber in spiral form and further mix uniformly with liquid raw material that is sprayed through the high-speed centrifugal sprayer into extremely fine mist. Upon mixing with hot air, the raw material fine mist will be vaporised and dried instantly. Final product in powder form is discharged continuously from the bottom of the drying chamber and also in cyclone separator. Heated air is discharged from exhaust fan outlet.

FEATURES

- Drying speed is rapid. When liquid raw material is atomized, the surface of the material will be enlarged greatly. In the hot airflow, 95% - 98% of water can be evaporated instantly. time of completing the drying is several seconds. This is especially adapt to dry heating sensitive material.

- Finished products have high quality, high-purity, good uniformity, good flow capability & solubility advantages.

- Simple and stable operation , convenient control and debugging, easy to achieve automatic operation.

APPLICATIONS

Chemical Industry: Sodium fluoride (potassium), alkaline dyestuff and pigment, dyestuff intermediate, compound fertilizer, formaldehyde silicic acid, catalyst, sulphuric acid, amino acid, white carbon and others

Plastics and resin: AB, ABS emulsion, uric acid resin, phenolic aldehyde resin, urea-formaldehyde resin, formaldehyde resin, polythene. poly-chloroprene and others

Herbs/Food Industry: Tongkat Ali, Belalai gajah herbs, Fatty milk powder, protein, cocoa, substitute milk powder, egg white (yolk).

Food and plant: oats, chicken juice, coffee, instant dissoluble tea, seasoning meat, protein, soybean, peanut

protein, hydrolysate and others.

Sugar: Corn starch, glucose, pectin, malt sugar, sorbic acid potassium and others.

Ceramic: Aluminium oxide, ceramic tile material, magnesium oxide, talcum and others.

PROCESS FLOW DIAGRAM

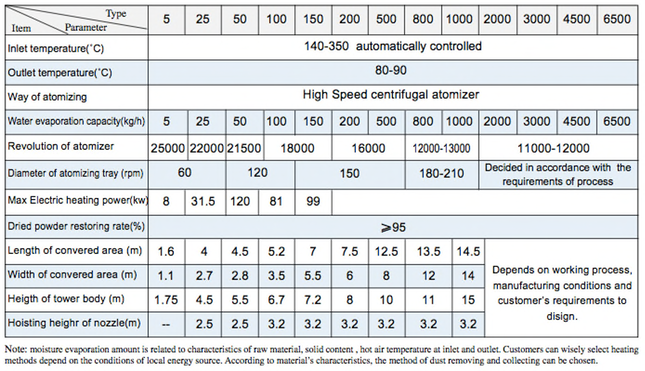

TECHNICAL SPECIFICATIONS