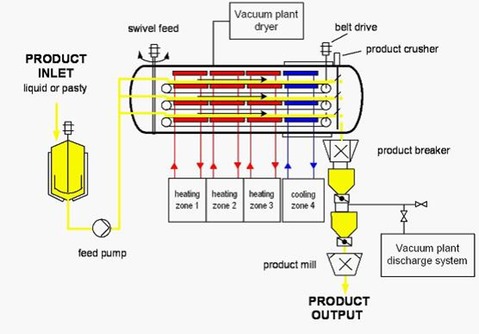

vacuum belt dryer

GENERAL

This type of drying reduce traditional drying time from 10-20 hours to 30-60 minutes (depends on materials), to reach the goal of adjusting drying temperature according to different materials, which solve the problem difficult to spraying drying, and another problem that traditional drying oven spend a long time causing the material to loose its texture, taste, and color.

WORKING PRINCIPLE

Vacuum belt dryer can accomplish continuous feeding and continuous discharging of material in vacuum state, turn the traditional static drying to dynamic vacuum drying.

FEATURES

- Automatic and continous operation

- Continuous feed-in & discharge in vacuum state

- Final product is in dry and granulate condition

- Temperature adjustment depends on type of raw material

- Moisture content of product can adjusted

- Keep heat-sensitive material property & clean

- Keep fragrance, good dissolubility

- Continuous discharge after 30-60mins, collecting rate reaches 99%

- Operate with all kinds of liquid & solid raw material

- Automatic CIP operation according to GMP requirement.

VACUUM BELT DRYER MODELS

Please email us your specific requirement.

APPLICATION

Vacuum belt dryer (VBD) is used in drying all kinds of liquid or paste, such as Western medicines, foodstuff , biological products, chemical material, health food, food additive, and etc, especially suitable for drying material which are high-viscosity, easy for mass formation, or thermoplastic , with thermal sensitivity, or not be dried/not suitable by means of spray dryer. For these materials, Vacuum belt dryer is the best choice.